Conclusion#

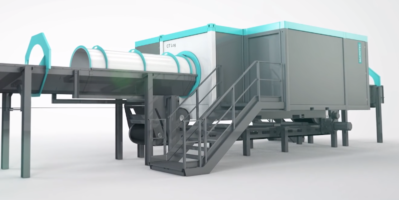

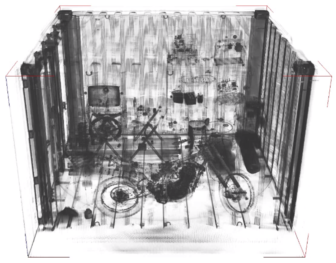

X-ray imaging is mainly limited by the thickness of the part to be checked. The detectability of plane defects is less good than in ultrasound, but automation of control is very easy.

Pros

no coupling

2D(+t), 3D(+t) imaging

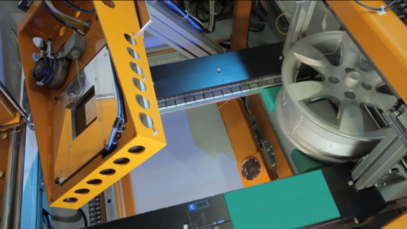

metrology

volumic defects: good sensitivity

automatization

Cons

radioprotection & cost

crack, delamination, planar defect: poor sensitivity

large thickness: poor transmission (\(>\) a few cm of metal)

Fig. 193 Pablo Picasso The Old Guitarist, 1903 – Visible (left), IR (middle left), X-Ray diffraction (middle right), and outline (right)#

Multimedia: